1. Cause of the stick-slip effect

Causes are mutual hooking between the microstructures of the body surfaces on the one hand, on the other hand intermolecular forces between the bodies (adhesion). In addition, the stick-slip effect also depends on the sequence of motion of the bodies in contact

Causes are mutual hooking between the microstructures of the body surfaces on the one hand, on the other hand intermolecular forces between the bodies (adhesion). In addition, the stick-slip effect also depends on the sequence of motion of the bodies in contact

2. What is the impact of the stick-slip effect?

The stick-slip effect propagates via structure-borne sound – depending on the damping of the material pairing – and can lead to very unwanted noise, for example in vehicles. We know this from creaking and squeaking doors, rattling windshield wipers or creaking noises in vehicle interiors. In addition, stick-slip, much more than uniform friction, can lead to increased wear and material fatigue, and can also completely stop the slightest movements in precision machines, threaded spindles and other drives.

The stick-slip effect propagates via structure-borne sound – depending on the damping of the material pairing – and can lead to very unwanted noise, for example in vehicles. We know this from creaking and squeaking doors, rattling windshield wipers or creaking noises in vehicle interiors. In addition, stick-slip, much more than uniform friction, can lead to increased wear and material fatigue, and can also completely stop the slightest movements in precision machines, threaded spindles and other drives.

However, the stick-slip effect also has a bright side. Without stick-slip, there would be no string instruments that bring us the highest listening pleasures in music.

3. What factors influence the stick-slip effect?

Just as the physical properties of materials can change due to the influence of temperature and humidity, the climate also influences stick-slip behavior. This often increases at higher temperatures, as in the case with leather and artificial leather in contact with itself or with hard plastics.

Other polymer materials, such as polyamide (PA), react to high humidity with an increase in the stick-slip effect. Components made of elastomer materials, such as seals in combination with glass or painted surfaces, are also prone to stick-slip-induced vibration and squeaking when exposed to high humidity.

Factors such as relative velocity also influence noise behavior. Solids with soft surfaces have a higher tendency to stick-slip at low speeds, while many hard plastics exhibit the opposite effect. Countermeasures must then be adapted accordingly.

The impacts of the stick-slip effect with regard to noise generation are always dependent on the natural frequency of the component and thus also on its mass.

In material development, the avoidance of stick-slip is therefore a growing aspect of material requirements.

4. How is the stick-slip effect measured?

Now the question arises, can stick-slip be measured?

Now the question arises, can stick-slip be measured?

If so, how?

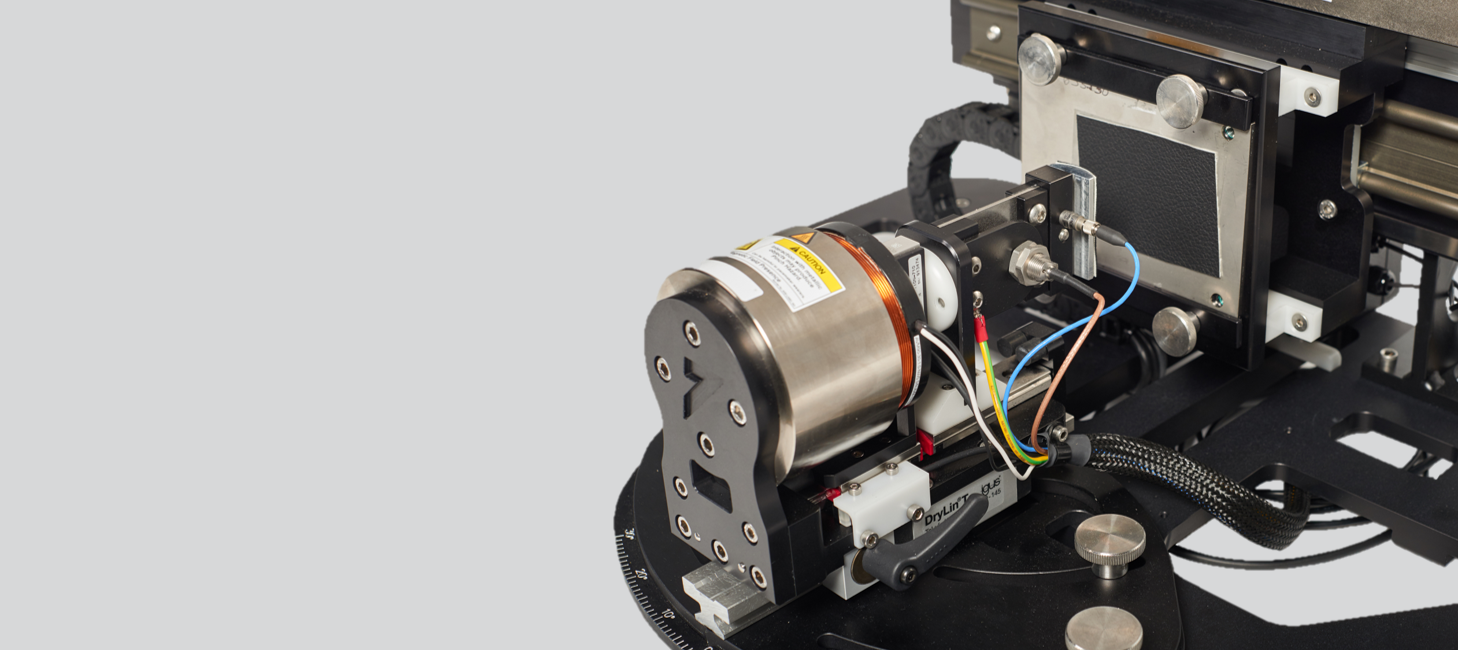

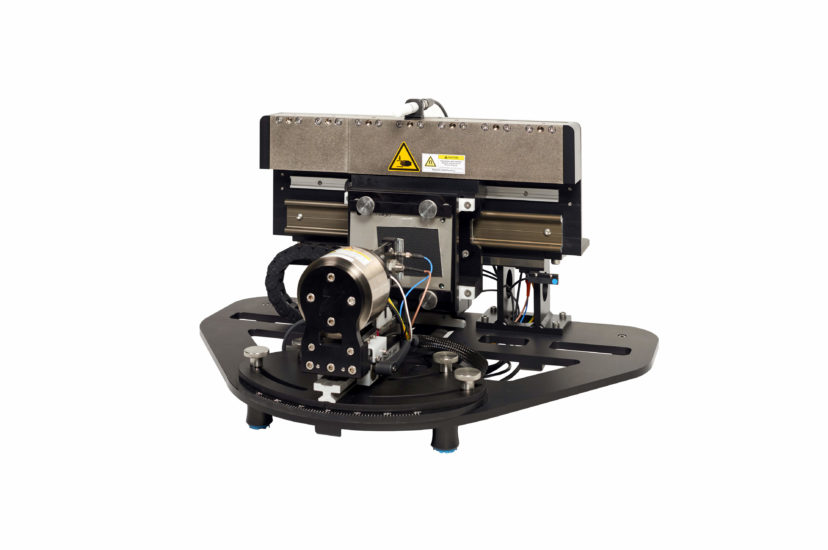

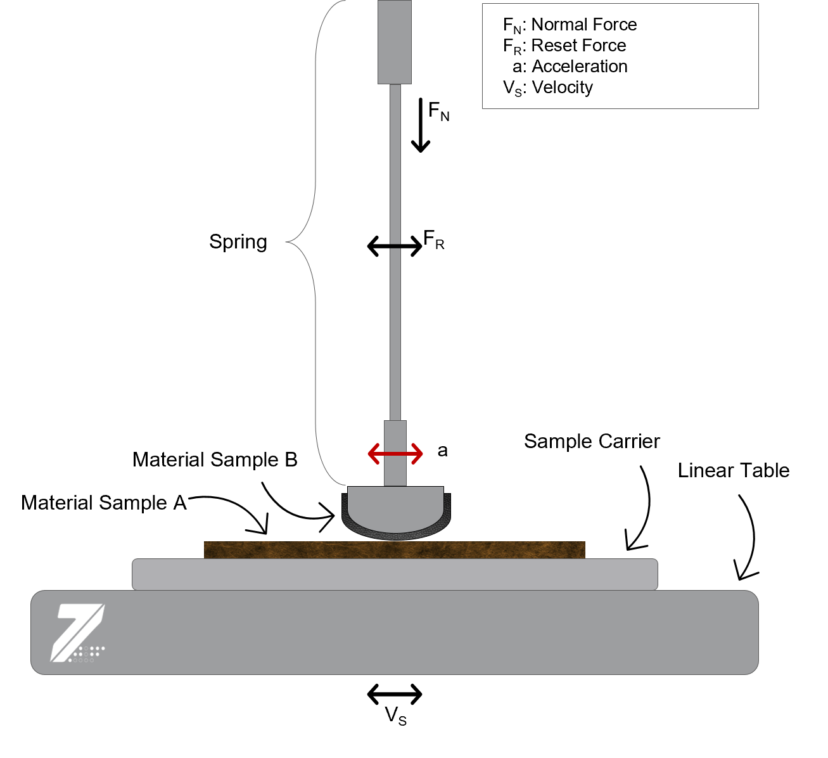

We developed and launched the first stick-slip test rig 20 years ago using a patented test method. In this method, two materials are brought into contact with an adjustable normal force and mutually moved transversely at a speed that is also adjustable (see sketch of the operating principle). The static friction deflects a flat spring in the direction of the movement.

At some point, the restoring force of the spring exceeds the static friction of the two materials, and there is a sudden transition from sticking to sliding. Energy is released in that process. We determine this energy with the aid of an accelerometer.

5. Industries affected by stick-slip

It is not only in the automotive industry where materials get into contact with each other as a result of different vibrations and at different temperatures, which can lead to a stick-slip effect and the associated anoyingnoises.

Annoying noises such as squeaking, creaking or cracking are undesired just as stagnant motion sequences and the resulting malfunctions. This statement applies to almost every application and requirement, and that is why we work together with a wide variety of industries.

5.1 Automotive/VDA 230/206

In passenger car interiors material pairings of genuine or imitation leather are often found – not only in the luxury segment – which are frequently responsible for annoying noises. The resulting customer complaints and the associated high costs for car manufacturers led the VDA (German Association of the Automotive Industry) to issue a test standard (VDA 230/206) in 2005 to address precisely this problem.

In passenger car interiors material pairings of genuine or imitation leather are often found – not only in the luxury segment – which are frequently responsible for annoying noises. The resulting customer complaints and the associated high costs for car manufacturers led the VDA (German Association of the Automotive Industry) to issue a test standard (VDA 230/206) in 2005 to address precisely this problem.

Most German and numerous global automotive manufacturers have adopted this VDA standard 230/206 in their test specifications with the aim of ensuring that their suppliers supply stick-slip-free materials. Leather, for example, can be optimized by a modified finish. In the case of artificial leather, this is achieved by a modified material formulation.

5.2 Household appliances/white goods

In the case of household appliances, the stick-slip effect can also be reflected in the form of unpleasant noises, which is particularly critical in private homes. For example, fridge-freezers can make such loud cracking noises that the residents get frightened or even their sleep gets disturbed.

In the case of household appliances, the stick-slip effect can also be reflected in the form of unpleasant noises, which is particularly critical in private homes. For example, fridge-freezers can make such loud cracking noises that the residents get frightened or even their sleep gets disturbed.

In our laboratory we can perform various tests using specially installed structure-borne sound sensors and microphones, so that the exact area can be localized as the source of the noise.

In the next step the causal contact points are located in order to find out where the relative movement comes from, which is responsible for contact points causing noise at all.

5.3 Lamps

The stick-slip effect can also occur in lamps, which is manifested by creaking, squeaking and also cracking noises.

They are caused by temperature changes in the lamps, which entail constant material expansion and shrinkage. This causes relative movements due to incompatible material pairings.

5.4 Medical technology

A good example are insulin pens as aids for diabetics to administer a precisely defined amount of insulin easily and accurately.

A good example are insulin pens as aids for diabetics to administer a precisely defined amount of insulin easily and accurately.

The rotary knob for dosing has a detent mechanism with acoustic and tactile feedback so that people with visual impairments can accurately dose the amount to be administered. The sliding phases in the detent mechanism must not be interfered by anything in order to avoid operating errors that would have fatal consequences.

In our example, incompatible material combinations within the insulin pen caused stick-slip and impeded acoustic and tactile feedback. We were able to determine the critical material pairings by measurement and successfully assist our customer in finding alternative materials.

5.5 Lubricants

Lubricants are often used to reduce or even eliminate the stick-slip effect between two components or materials.

Lubricants are often used to reduce or even eliminate the stick-slip effect between two components or materials.

Unfortunately, it turned out that under various contact conditions, certain lubricants either do not help or even make the situation worse due to insufficient lubrication. The root cause is on one hand, the lubricant does not match the materials of the friction partners, and on the other hand, it does not match the contact situation.

In our physics laboratory we are able to use the H3P test rig to measure the stick-slip effect between material pairings under the influence of lubricants. Thus we achieve an important contribution to avoid annoying noises and optimize abrasion and wear properties.

5.6 Bicycles

Stick-slip effects can also lead to restrictions in the customer’s positive product perception on bicycles, for example when pedaling. By using our test rig, responsible contact points can be identified, such as the sprocket wheel in contact with the chain. In combination with our experience a suitable coating for the sprocket wheel can be determined that prevents stick-slip in a sustainable and long-lasting manner and restores the positive product perception of the end customer.

5.7 Furniture

Every day, we encounter situations in which the stick-slip effect can occur. In Germany, people sit for an average of 7.5 hours a day. Not only when sitting down, but also when sitting up, standing up or doing a little work out in the office chair, squeaking, creaking and cracking noises can occur. That is caused by the horizontal force induced by the user’s own weight.

Every day, we encounter situations in which the stick-slip effect can occur. In Germany, people sit for an average of 7.5 hours a day. Not only when sitting down, but also when sitting up, standing up or doing a little work out in the office chair, squeaking, creaking and cracking noises can occur. That is caused by the horizontal force induced by the user’s own weight.

During movement, the spring force in the office chair make some materials rub against each other, resulting in noises. The stick-slip effect can also occur when the chair surface gets into contact with trousers (e. g. fabric on leather)

5.8 Mechanical engineering

In guides, bolted joints and other situations where solids are in contact and induce relative motion, the stick-slip effect can result in undesirable effects. These can be annoying noise, vibration, interfered precise movement and increased abrasion and wear.

In guides, bolted joints and other situations where solids are in contact and induce relative motion, the stick-slip effect can result in undesirable effects. These can be annoying noise, vibration, interfered precise movement and increased abrasion and wear.

For example, the ship’s shaft bearing of a submarine may be affected, which generates significant vibrations due to the stick-slip effect and would therefore be easy to locate in a serious case while under water. The tests that we can perform using our test rig on separated samples with the addition of seawater enable us to simulate the situation during cruising and create a solution

6. Measures to prevent the stick-slip effect

- Reduction of static friction by lubrication

- The addition of certain additives can influence the sliding properties of plastics

- Decoupling of the contact by means of sliding-optimized films or by felts

- Changing of the contact area and thus of the adhesion

- In case of contacts between hard and soft materials the adhesion can be strengthened by specific modification of the contact geometry in such a way that relative movement is excluded

- Relative movement, and thus stick-slip, can be achieved by a form-fit or even material-fit connection of the components